centrifuge for liquid liquid separate|russell finex liquid base separator : purchaser An industrial centrifugal separator is a sophisticated, high-performance device that leverages the power of centrifugal force and a mesh screen to separate liquids from solids. This state-of-the-art equipment operates by spinning mixtures at high speeds, thereby causing solids and liquids to separate with the help of a woven mesh screen. Pour protéger vos bois, optez pour nos huiles de lin de première qualité et nos produits de traitement du bois composés d'huile de lin pour une protection optimale.

{plog:ftitle_list}

While 121 degrees Celsius isn’t necessarily a magical number, it serves as a general guideline for accommodating a wide range of commonly used lab media. However, there may be exceptions based on specific .

Extraction, a two-stage process involving mixing and separation, is applied in analytical and micro-chemical technology for purification and analysis of fine.Comprehensive 2-Phase Separation Solutions & Services. Trucent comprehensively address your centrifugal fluid purification and solid-liquid separation needs. We can help you maintain your existing centrifuges and decanters—or design an entirely .An industrial centrifugal separator is a sophisticated, high-performance device that leverages the power of centrifugal force and a mesh screen to separate liquids from solids. This state-of-the-art equipment operates by spinning mixtures at high speeds, thereby causing solids and liquids to separate with the help of a woven mesh screen.These liquid / liquid separation centrifuges, also known as annular centrifugal contactors, offer the following advantages and benefits: Direct motor coupling to the main shaft; Short retention time and low liquid holdup; Well adapted to batch or continuous operation;

Rousselet Robatel Liquid-Liquid Separation Centrifuges. Centrifugal Separators BXP; Operating Principles ; France / Headquarters. ROUSSELET S.A. Avenue Rhin et Danube, Zone Industrielle Marenton, 07104 Annonay, France Phone: 33 (0) 4 75 69 22 11 Fax: 33 (0) 4 75 67 69 80 [email protected] It is from these zones that the light liquid and heavy liquid are extracted. Centrifugal Liquid-Liquid Separation. Rather than relying on gravity, centrifuges use centripetal acceleration to apply up to 3,000 times the force of gravity. This force and the internal coalescing plates drastically shorten separation times and allow separations at . Centrifugal separator are driven by the technique of centrifugation and it is designed for liquid-based applications. It is separates two liquids of different densities, and phases. In this blog, get details of Centrifugal separators working principle, types and features. Liquid separation principle The centrifuge generates centrifugal force through high-speed rotation, which causes different components in the mixed liquid to separate into layers according to their density differences. The components with higher density move to the edge of the centrifuge container under the action of centrifugal force, forming the outer layer, while the

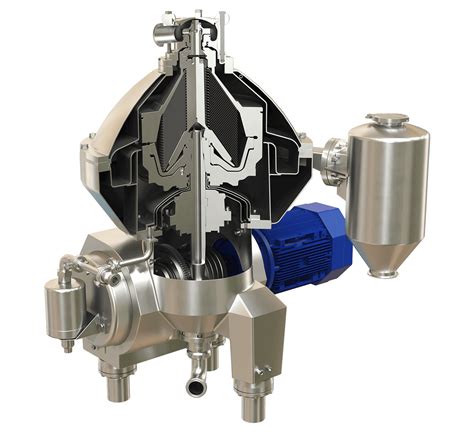

Figure 1: Model BXP liquid / liquid separation centrifuge When operating as a liquid / liquid centrifugal separator, a mixture of two immiscible liquids (shown in green) with different densities is fed to the pumping chamber located on the bottom of the centrifuge housing. The liquid / liquid mixture is aspirated into the centrifuge bowl by a .Three-phase decanter centrifuge is an efficient and reliable centrifugal solid-liquid separation equipment that rapidly separates mixtures into two distinct liquid phases and one solid phase. It is widely used for three-phase separation in various industries, including food waste, as well as liquid separation in applications such as edible oil .GEA separators are designed for liquid-based applications. Using centrifugal force, they are used for separating suspensions consisting of two or more phases of different densities, i.e. they can be used for liquid-liquid separation, for liquid-liquid-solid separation or for liquid-solid separation. They are equally as effective at separating liquid mixtures at the same time as removing solids.A filter centrifuge functions as a clarifying centrifugal separator (liquid/solids separation). A clarifier (clarification separation) uses centrifugal force (g force) to separate solid materials from a liquid phase. The solid material collects against the centrifuge bowl wall (solid wall). A proper clarifier has a stack of conical discs (disc .

The CentraSep DX Series of disc stack centrifuges can dynamically switch from being a three-phase separator to a two-phase separator, effortlessly moving from liquid-solid separation to liquid-liquid-solid separation. This makes the DX an asset in many facilities, where it can be deployed at several different stages in a single production process.Liquid / liquid separator, annular centrifugal contactors, liquid / liquid centrifuge, centrifugal separator; Liquid/Liquid Separation/Extraction. Rousselet Robatel is a worlwide leader in designing and manufacturing a high range for different industries such as Chemistry, Pharmacy, Cosmetic, biotechnology, Textile, Metalworking and food . Download Citation | Solid-Liquid Separation: A Guide to Centrifuge Selection | Guidelines for chemical engineers to build a better understanding of centrifuge selection in pharmaceutical and .

A clarifier is a centrifugal separator for solid – liquid separation, that removes solids such as particles, sediments, oil, natural organic matter and colour from process liquids. In doing so, the process liquid becomes clear. Purifier. A purifier is a centrifugal separator for liquid – liquid – solid separation, that separates two .

what is centrifugal separator

However, for liquid–liquid separation centrifugal equipment – e.g., tube centrifuges – only superficial knowledge and less detailed investigations are given Extraction, a two-stage process involving mixing and separation, is applied in analytical and micro-chemical technology for purification and analysis of fine. However, for centrifugal liquid–liquid separation only few detailed investigations for sedimentation and even less for coalescence phenomena are given in literature (Jammoal and Lee, 2015, Otillinger, 1988). Other researchers quantified separation kinetics and efficiency for centrifugal oil–water separator with plate pack internals (Plat .

Gas/Liquid Centrifugal Separators are designed to separate entrained liquid droplets and solids from a gas stream. They are sometimes referred to as vortex separators due to the underlying principles of conservation of angular momentum, tangential velocity, and resulting centrifugal inertia driving droplet separation. () = can be done but not usually used for this purpose. III. Types of Centrifugal Separations. 1. Differential centrifugation. Separation is achieved primarily based on the size of the particles in differential centrifugation.This type of separation is commonly used in simple pelleting and in obtaining partially-pure preparation of subcellular organelles and .Removes solid particles from a liquid phase. PURIFIER (separator) Separates a heavy liquid from a main light liquid. Generates a purified light liquid with the simultaneous separation of suspended solids. CONCENTRATOR (skimmer) Separates a light liquid from a main heavy liquid. Generates a clean heavy liquid with theB&P Littleford offers Liquid Liquid Extraction with our Podbielniak Centrifugal Separator. This machine is perfectly suited to optimize this process. Call us now! 989.757.1300 . About; News & Events; . The reasons behind using an extraction process such as liquid-liquid separation vary, but you may consider this process when: The material is .

A clarifier is a centrifugal separator for solid-liquid separation, that removes solids such as particles, sediments, oil, natural organic matter, and color from process liquids. In doing so, the process liquid becomes clear. Purifier. A purifier is a centrifugal separator for liquid – liquid – solid separation, that separates two liquids .The diagram above shows a three-phase (liquid-liquid-solid) centrifugal separation process. First, commingled water/oil/particulate flows into the bowl through a feed pipe (1) and into the distributor (2), where it is accelerated until it reaches the bowl’s rotating speed. It is then conveyed to the bowl (3) where the separation takes place.The separated solids collect at the bottom of the separator and discarded. High-density liquid, such as water, flows out of the separator. Low-density components, like oil, remains inside the centrifugal separation machine. Centrifuge Separator Manufacturer. B&P Littleford is a centrifugal separator manufacturer and we supply the ideal . As well as solid-liquid separation, two liquid phases with different density can be separated taking advantage of their different inertial behaviour under a force field. This is the case of centrifugal decantation where a multiphase liquid mixture is continuously fed at the center of .

The separation process involves a combination of gravity, centrifugal force, and other mechanical or electrical forces to separate the gas and liquid phases. The main purpose of a gas-liquid separator is to remove liquid droplets from the gas stream to protect downstream equipment such as compressors , turbines, and pipelines.

solid liquid separation equipment

russell finex liquid base separator

liquid centrifugal separator b

Our Hydrothermal Autoclave Reactors are designed for precision, reliability, and efficiency. Perfect for a wide range of applications from material synthesis.

centrifuge for liquid liquid separate|russell finex liquid base separator